As expected, the generator hookup for the W.O.G. worked perfectly the first time. It’s also not the first time. I’ve installed two of these before and they’re not complicated in the slightest. The only hard part, it turns out, is finding a good place on metal siding to mount it!

One of the nice things about having the generator hookup in place, though, is that while I cannot run my table saw (currently) on my solar power system, I know it runs ok with the generator and I can put my solar power system on bypass which lets the generator power flow into the loads directly, without involving the battery or the inverter at all. Translation: it’s about the same as hooking the generator directly to the panel, but with the advantage of being hard-wired in such a way that I no longer need to pass wires through open doors to do it. Result: benefits of generator power (enough juice to run the saw) without the immediate personal drawbacks: noise, exhaust, and cold air coming in through the open door. It’s still not what I want but it’s quite a lot better than what I had. I’m still noodling about how to solve the power problem permanently.

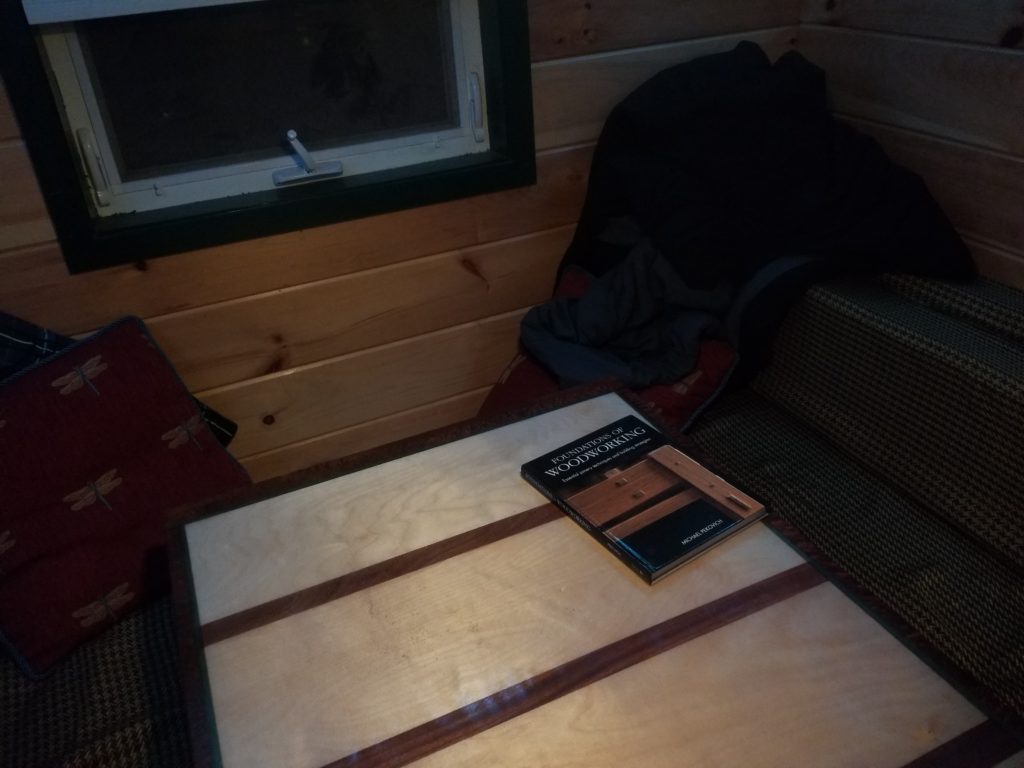

Meanwhile, since I can at least use the saw and keep the weather out, I can put it to use cutting plywood to dress the window openings in the workshop, like this:

This is far quicker, neater, and more accurate than cutting with the circular saw, which is what I did for the office windows. Boxing out the windows is necessary to contain the insulation and it also helps to secure the inside stud wall to the exterior framing. I mean, besides also making the window recess look nice and giving me a place to set stuff down 🙂

These window recesses don’t have to be beautiful – it’s just a utilitarian workshop. Indeed, in some of them you can see the sharpie markings where I wrote down their dimensions prior to cutting and there are gaps which will not receive any trim or filling to conceal them. Still, even just this much treatment of the space makes it look better, as well as being functional. It brightens the room a bit, too, since now light isn’t lost into the insulation but is partially reflected to the interior. You can see the plywood illuminated.

As you can see, the workshop is a long, long way from being set up properly – the table saw is just sitting in the middle of the floor, no outfeed table, no good working room around it. But at least I can use it to help do that proper setting-up, which includes finishing the inside walls, which includes this window dressing.

It was a weekend of odds-and-ends. Two doors which I’ve had on hand for at least a month, if not two, which were destined for openings in the mud room have now been installed in the mud room.

The new doors go from the mud room to the workshop and the garage, respectively. This, in turn, makes it possible to install the rest of the wallboard in the mud room, which, in turn, makes it possible to do all the rest of the finishing in there. That’ll be a nice bit of progress – I go through that space to the office every day. Having it look done will be good.

What’s nice about pre-hung doors is they already have the jamb aligned to the door and cut-outs for the door hardware. What’s problematic about that is if one makes an error, there’s really not any meat left on the jamb to do a second try. I had an idea how to deal with that, though. I cut the recess I needed to position the strike plate and since the jamb couldn’t take the short screws that came with the hardware any more, I put a backing board and used much longer screws to get purchase on it, going right through and past the chewed up bits of jamb from my first try. When the wallboard is on, nobody else will ever know – unless they look at the strike plate and wonder why there are tan screws on black hardware…

I don’t have big plans for the mud room, but there is a place carefully sized for a boot bench I built some time ago for a very different house in a very different life.

Having the table saw running also meant I could make some of those long-awaited shelves for the house. It may not look like much, but adding these means I can now unpack much more of my homegoods into the home, making room where they had been stored as well as making the homegoods themselves useful.

Another odd-and-end was installing a window blind in the office. The afternoon sun streams right in through the window, into my eyes. On the one hand, that’s actually on purpose — I wanted the room to be full of sunlight — but for an hour midday, it’s just too much. Hence the blinds. The store has a purpose-built machine for trimming the width of the blinds, but of course when I bought mine, the machine was out of service. Having installed three of these already in the house (without need to trim them), it became apparent to me that cutting them really didn’t have to be a “store associate only” operation using their special machine. I just needed some care. I compressed the blinds tightly and sandwiched the unit between a pair of sacrificial 2x4s and went at it gently with my chop saw.

The cut was clean, even with the very aggressive construction blade I have in the chop saw. It went through the plastic and cloth like butta. The key here is to hold the work securely and support it against all the forces of cutting so it doesn’t chip out or crack or bind up the blade in a tangle of cloth fragments. That, and bringing the saw to the work slowly, so that the forces exerted by the teeth are seen by just a small fraction of the sandwich at a time, reducing the chances of cracking or taking out a big chunk of material that could foul the blade or simply ruin the blind.

Now with the workshop window recesses dressed and the doors in the mud room installed, I am able to move both of those projects forward with greater ease. This will consume my wallboard stock and my insulation stock, which in turn increases the amount of space in the workshop and garage, which makes everything more betterer. Also, getting the shop walls closed in will be a major milestone. Once that’s done, I can install the French cleat mounting system for tools and jigs, as well as push my storage shelving to the walls where they belong, out of the main floor area of the workshop. This will hugely improve the utility of the room. And its safety, too, for that matter. Of course having things be more done is also a reward in itself.

Another odd-and-end was the simple act of hanging this curtain in the doorway to the T.H.R.O.N.E. room. As a person living alone, I really had no particular motivation to put a “door” of any kind on the bathroom, though from a pragmatic point of view, it would help keep it warm and cozy when using the tub. More importantly, though, at least one visitor was a little put out by the fact of there being no obvious privacy in the bathroom. In point of fact, the T.H.R.O.N.E. itself is recessed in a cove such that only ones knees might be visible from the main part of the house while doing one’s business, but even so, to mount or dismount from the T.H.R.O.N.E. with one’s knickers down, well, that would be a show for anyone who happened to glance in that direction. Now it’s more civilized.

There is another significance to this curtain, far beyond the comfort and modesty on the rare occasion of a visitor. THIS is what was significant about it:

To you, this is a fairly ordinary view through a window featuring a FedEx truck making a rural delivery in winter. To me, it is the receipt of the curtain’s tension rod. That, of course, is not the significant part. The significant part is that until this day, FedEx had lost 100% of packages it carried that were destined for me at this address. Without fail, the packages would show in tracking making their way to a depot about 30 miles from here, then show “address corrected” and a few days later “delivered” – but each time to a different place and NO time to my house. Various attempts to use their help line failed miserably. Last week, I had the idea to actually see if I could find a phone number for that specific depot and try to talk to a local person about these so-called “corrections”. I did actually find such a number and called. They assured me they were not at fault and instead an urban office 50 miles away was. No, it’s them. But they were clearly not ready to help me, so I called the other office, hoping at least to reach someone who cared and could be my advocate from the inside. INDEED I DID! The lovely clerk reached out to her colleagues in that other depot (the one actually at fault for re-addressing my packages) and set them straight about my address being legit and giving them my instructions on how to find it (not complex at all – my road is directly opposite an intersection with another road that is established and therefore on maps). This FedEx truck arriving brought not only the tension rod for the curtain, but also the most recent mis-routed package that actually was in the domain of that urban office, as well. One recovered of three, but better than nothing. More importantly, it seems at least for one day the local depot came to understand where I live. I am hopeful that future shipments will actually make it here, too. And if they don’t, I have the number of a person I can call who cares. And that’s something.

In other randomness, I installed some additional lighting in the BeDiLiA. What was there is plenty for computer work, watching movies, dining, etc., but it’s not really in the right place for reading. The center of the table is not where the books are. Indeed, I like to shuffle into the corner and lean up against the wall, using the Bednette bench as a bit of chaise lounger. There’s no good light back there, though. Well, there is now. I still need to finish the permanent wiring of it, but the fixtures are installed and they make a huge difference. This shot with new lights off, then on, same exposure.

And lastly, in today’s Odds & Ends report, the exchange of one of the two battery modules for the W.O.G. On top of the power supply issues for the table saw, one of my two battery units refused to play nice with the other one, effectively halving my available storage. You may recall I bought the second unit just a few weeks ago! That second unit was actually working fine. It’s the original battery I bought some time ago that was misbehaving. What’s extra fun about this is that these units weigh 230# before you even start to factor in the shipping crate. Moving those crates around and getting the modules in and out of said crates is no trivial matter for somebody working solo. Even if that somebody is a big brute like myself. So how DOES one get a roughly 300# box from the floor to the cart so it can be brought outside to be picked up for the exchange? Never mind how does one gently place a 230# unit on its back into a crate on the floor!

shimmy it forward, and strap it down.

I bought this little cart years ago to make it easier to move my yurt around in the woods when I would bring it for camping at festivals and such. I used it for that a few times, but it’s been getting much more use here in TINBIDIA, both schlepping 300# crates of batteries around as well as routinely bringing loads of firewood from the bandsaw station back to the house (the cart has removable sides which when installed nicely contain the wood).