So one fine day, this truck arrives at my house…

…and the driver gets out and says “how are you going to unload this stuff??”, referring to the slightly over 1000# of 3″ galvanized steel pipe he’s brought me. Unloading a thousand pounds from a truck at loading-dock height is kind of a big deal if one doesn’t have a loading dock.

However, I also know that the individual pipes don’t weigh more than about 110#, and while that’s still pretty heavy, especially since those pipes are also 14 feet long and therefore also quite awkward to control, I can actually manage them one at a time. So that’s what I do. Cut the binding straps, slide them out by ones, and land them on the driveway (somewhere close, to minimize carrying and to let the delivery driver get on with his day as soon as possible). Thankfully, the short (7′ and change) pipes were in a box that could be maneuvered all at once. Still well over 200# but using some pivoting leverage as well as considerable brawn, I was able to land that relatively gently.

Of course, those pipes are acutely in the way of the cars so obviously they need to move one more time. But what are they here for, anyway? The answer is these are the foundation of the solar arrays. Two shorter pipes (in front) and two taller pipes (in back) crossed by two of the longest pipes, create something akin to a gymnast’s un-even bars, creating the framework on which the rest of the solar hardware is assembled. Two arrays = 12 pipes. These turned out to be surprisingly expensive (many $100s each, times 12 pipes…) as well as quite heavy.

The driver, who is willing to help slide the pipes off the end of his truck, certainly isn’t going to help me actually carry them. So that’s all me – landing 1000# of pipe once, then carrying them all again to a more organized staging area for the night.

So a thousand pounds moved twice: I lifted a ton of pipe.

Then I double-checked their measurements. Eleven pipes were perfect. One was 2″ short! Conveniently, the shorter one is meant to be a vertical post in 5 feet of concrete, so if instead it is in 4ft-10″ of concrete to meet the others at height, that’s fine. Still, it was annoying. I also checked that the solar racking hardware that goes on the pipe ends actually fit on the pipe ends — if it didn’t I had a very expensive problem. Happily, yes, it fit fine. Okay, all good, then. But the pipes are in CT and the solar arrays will be elsewhere… better get them on site soon, so when the excavator who is doing the site work is ready, they’re ready for him.

Time to rent a big truck. They’ll rent you a big truck for $40/day… but for $1.09/mile. And at 10MPG nominal, those miles are gonna cost you in fuel, too…

I had the presence of mind to lay out some retaining straps before loading the pipes so when they were all loaded, I could bundle them securely. And instead of actually carrying the pipes, which would put a fair bit of strain on my whole body, managing their weight and torque, I thought to drag them into place, thereby only bearing about half their weight and no in-air dynamics to manage. I brought them to rest on the edge of the truck deck, then lifted the far side, letting the truck bear the other half of their weight, and just slid them in, mostly in contact with just the edge of the deck, reducing friction considerably. This worked brilliantly and left me far less fatigued than I would have otherwise been. Good thing, because there’s another 1000# of gear to load.

Wait… whut?? Yeah. I figured as long as I have to pay for so many miles of driving this truck, the least I could do is make it worthwhile by bringing as much stuff on site as I could. My friend who owns the property happens to have a storage cabin there where I could stow a bunch of stuff, so that became my plan. Alrighty, then, time to load the battery module (>200#) and a bunch of other hardware.

The battery module was gonna be the hardest one – at well over 200# and bulky, there was no way I was going to be able to lift it myself. I can, in fact, lift and carry 200#, but not when it is shaped like a big, bulky box with hard corners and sharp edges. Garden cart to the rescue! Chock the wheels, tip the battery module back, lever it onto the cart, then a big heave-ho to get it fully on the cart. Roll it out to the truck. Strap it down securely to go up the ramp, pull it up the ramp…

…and the back of the module slides off the back of the cart, doing its best motorsport wheelie impression, trying hard to break free from my control. I do manage to wrangle it back down – after catching M passing by and asking her to take a picture. I was very glad it didn’t take a real tumble – that module is like $5k to replace if it got damaged. I did eventually get it nicely stowed.

Next up, 12 solar panels, each about 7ft tall and 40″ wide. They don’t weigh a lot (~65#) relatively speaking, but being glass and bulky, represent their own challenges for loading.

Among those challenges was the fact that the truck was slightly listing because the driveway is not level. This meant the panels wanted to fall away from the wall (and go crash). This, obviously, was undesirable.

Through some clever rigging, leaning, and tying-off in groups, I managed to get them to stay in place decently enough. I hired M to help me carry them in. I could have done it solo, but thinking ahead to how fatigued the whole day was going to make me, any opportunity to lighten my load I was going to take. And she needed gas money. Win-win. After the panels were loaded and strapped in (green), I added secondary and tertiary restraints (dark rope), tied down to different things in the truck as best as I could locate, so if any single thing came loose, there was still a strong chance the panels would stay in place. They’re not actually the most expensive part of the system – just a few $100 each — but still, having them destroyed would be bad.

The power center (on cart, left) was last. As it turns out, the fuel filler pipe intrudes on the cargo area just a little, in the form of a boxed-out bit of deck material. This was the perfect wheel chock for the cart, so all I had to do was strap the cart to the wall. Between the chock and the door, that cart wasn’t going anywhere. So while this may not look like really all that much stuff, you’re looking at about $15,000 and 2000# of solar system goods. And a hand truck that U-Haul cleverly stowed to tempt me into using it. If I had needed that corner for storage but didn’t need the hand truck, that would have really annoyed me because to move the hand truck meant removing the seal that says you used it, creating an additional rental charge for the hand truck. Only $7, but still, kinda sketchy putting it there like that. And just cheap enough that people are unlikely to argue about it . . . so I bet they make a fair bit of money from doing this because people don’t fuss (or maybe they do?). Either way, not cool, U-Haul.

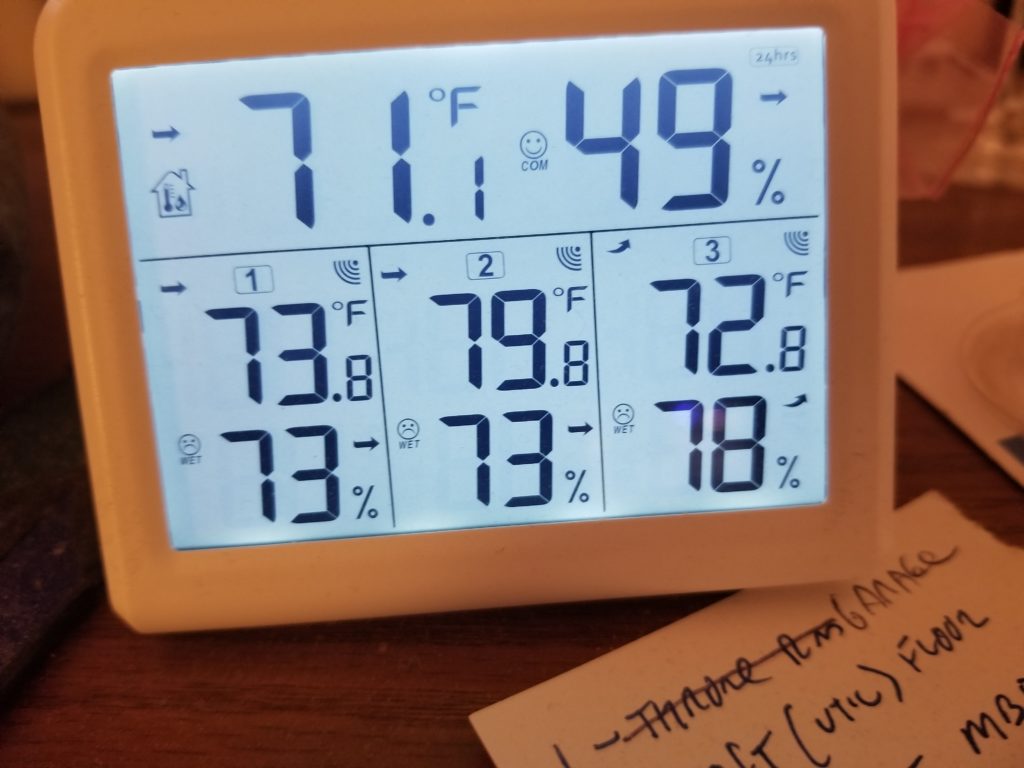

Okay, all loaded. But did I mention it was 78% humidity that day? Oh yes it was. #3 on the climate station is the outdoor sensor. A comfortable 73F but that 78%rh was killer. Still, I did manage to find a spot on my shirt that wasn’t sweat-soaked.

Before we continue the journey, there’s one bit of other work done since the last update. I gave the front door a solid sanding down with my spiffy new belt sander (beats the pants of the random orbit for big removal jobs like this), to get rid of the epoxy overspill from filling the gaps.

Now with the interior of the door looking all nicey-nice, it’s about time to drill for the hardware, apply some finish to both sides, and build the frame so I can get this thing installed for realsies. But not today. I have many other things already in process.

So about that truck. Loaded and good to go. The trip to the site was uneventful except that the truck itself was difficult to handle (even for a truck) and the engine and road noise in the cab were so loud I could just barely make out the streaming internet radio on my phone and for sure there were going to be no voice calls or podcasts. That’s too bad, since the truck itself really didn’t like going much over 60mph, which made the long trip somewhat longer than it is when I drive it in a car. Uneventful, but longer and more difficult than it had to be.

The destination is at the end of a long, narrow shale road which had been recently rained on. There was no place to turn around a heavy 24′ vehicle, that’s for sure. The chances of getting bogged down if I drove it off the road at all were significant. What to do? BACK IN. Yup. The road is about 800ft long. That’s a lot of backwards for a gently curving road that’s just slightly wider than the truck I was backing on it. Fortunately, my friend who owns the land was there and he gave me hand signals via mirror as I drove. It took about 10 minutes to slowly back that 800ft.

With his help, it was actually pretty quick work to unload and get all the solar stuff in the storage cabin, less the 8 pipes actually destined for installation in the ground which need to go to the part of the property where the HomeBox is going.

A few sights from the area… including that fancy chair swing I made for him as a thank-you gift, now installed by the lake:

So you know the old question about what bears may or may not do in the woods? Well, they do.

Right there on the driveway to The WOG. I anticipate learning quite a lot more about the local fauna once ensconced in my new abode. I already know a lot about how to stay safe in the wild, but on the other side of that, recognizing who’s been in the neighborhood and where they like to go / what they like to eat seems like good stuff to have in mind.

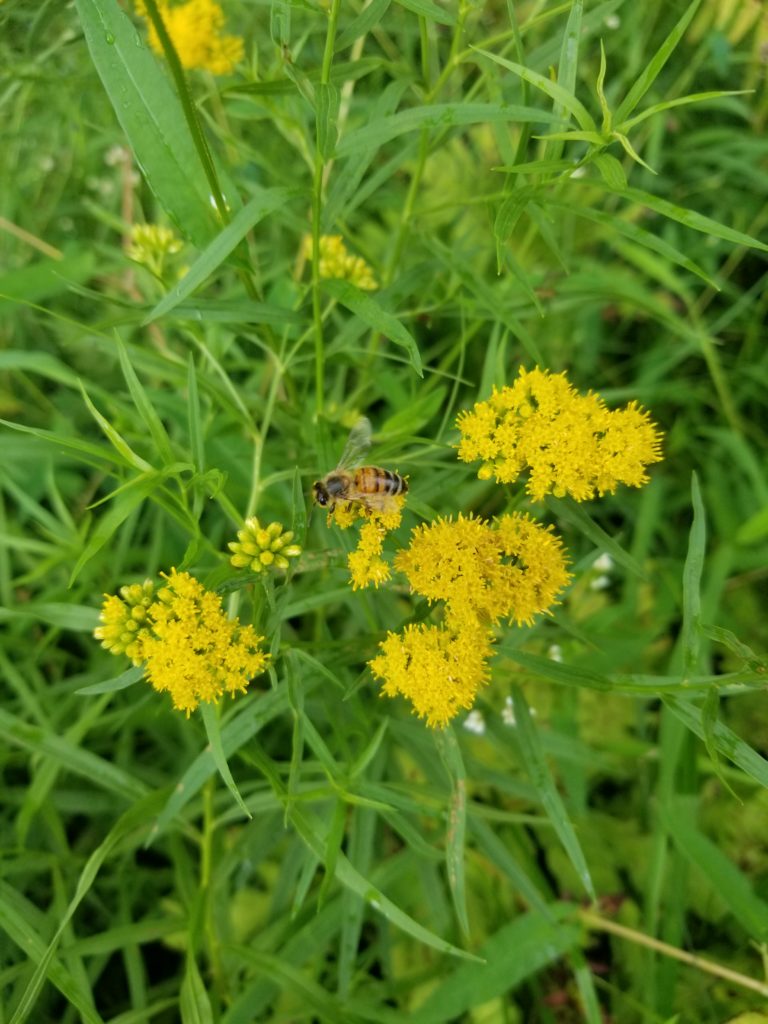

The area had a profusion of varieties of Goldenrod and Queen Anne’s lace, both of which I know honeybees really like in late summer.

This bodes well for the possible future apiary. There was goldenrod everywhere.

I also saw one of these extremely rare specimens:

I don’t know if it is alive or if this is just a dead shell, but even seeing just the shell is quite uncommon these days. Remember back before this species went extinct? They used to flourish at gas stations and parking lots and such.