Yesterday, the replacement battery modules arrived by freight, in excellent shape and right on time, if by “on time” we mean “they sat for more than a week in the warehouse but once they got moving, they got here promptly, considering they’re heavy freight”. This time I remembered to use my hoist to get them up to the loft, so no precarious acrobatics with expensive, 80-pound blocks of storage.

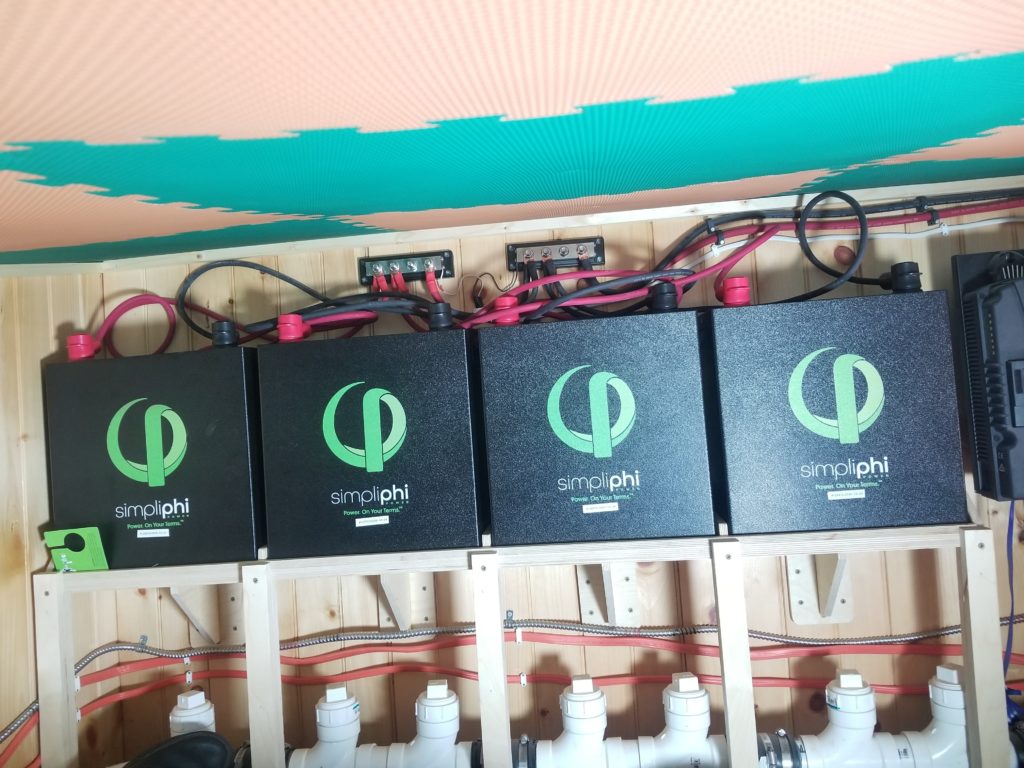

Once in the loft, it was time to hook them up and park them on the battery shelf.

Why so messy with the wires? Well, for electrical reasons, the wires to each battery must be identical in length. So the ones in the middle, close to the bus bars (metal things at the top), have a lot of extra wire where the ones on the ends have just enough to reach the deck of the loft.

Getting them there seems easy enough until you take a closer look at what’s required. Recall there’s very little headroom up here in loft land.

So I man-handle this 80# box until a corner of it is on the shelf, at which point I can have the shelf take the weight and then all I have to do is fuss with it and the heavy cables to get it in place. Not exactly a joy, but do-able. I learned it was important to do the outer batteries first so their wires were held better out of the way.

I did have some trouble hooking up the cables, though. The spec says torque the retaining nut to 160 inch-pounds, but don’t over-do it or you’ll wreck the module. Okay, I have a calibrated torque wrench for just such occasions, I’ll set it to 160 and that’ll be that.

Except it wasn’t. On some of the terminals, as I was dutifully torqueing away, they began to spin before I reached the official torque. Oopsie. They’re not supposed to do that, I don’t think. Obviously, I stopped immediately, but not before they had spun a little. Shit. Did I break it? These things cost nearly $3,000 each. Breaking one is a big deal. At the very least, it would mean sending them by freight back to the manufacturer in CA for repair, whatever the repair cost was, then freight back. For 320# of hazardous cargo (lithium batteries), that’s not an inconsequential freight bill. Gonna be less than $12,000 in batteries, but still. I have sent a note to tech support inquiring about whether the minor rotation of the studs is an actual problem. I kinda think it’s their fault, since there really wasn’t a way* to stop the studs from moving while I tightened the nut, but first we’ll see what they say before I start slinging blame.

*I did actually find a way to keep them from spinning – I could hold the lug with the wire very firmly with my left hand while I torqued the nut with the calibrated wrench with my right hand. It was difficult to absolutely immobilize the lug, but I managed pretty well once I figured out how. . . which wasn’t til after a few of them had moved. There was a second nut low on the stud that was pretty much impossible to reach because of a shroud. I managed to fashion an offset wrench to try to hold it, but it didn’t seem to make a difference.

No battery use until I hear from the manufacturer… which probably won’t be til Monday, so the weekend is shot for battery work.

How about the charger/inverter configuration, then? Sure. I can get these set up, at least. I had already made myself a checklist for bringing this system online – individual things to test and set as I go, proving out the parts one at a time, safely. I can do the parts that don’t involve the batteries. Okay, let’s do that.

BYPASS mode. This is where the generator is connected directly to the AC load center (breaker box). The entire power center is not involved with this except to actually make this bridge. I set this up. Applied “generator” power (plugged the generator cord into the outlet I made for this purpose in the garage). The outlet in the T.H.R.O.N.E. Room came to life as it should. I checked a 240V circuit, too (the well pump). All good, as I expected.

CHARGE mode. This is where the generator is connected through the charger/inverter which then charges the battery bank. Even with the batteries disconnected, I can power up the charger/inverter, see that it’s alive, go through the settings and configure it for the battery bank I’ve got, even though I’m not ready to enable that just yet. Switch set for CHARGE mode. Power applied.

Darkness.

No signs of life out of the charger/inverter in the power center at all. No lights. No self-test. No fans. No sounds of any kind. No smoke (happily). No fire (ditto). But no life, either (not so happily). No reasonable amount of button pushing would get me any response, either. Maybe somehow the power isn’t connected through?

I opened up the power center and carefully checked the supply wiring. It’s all correct as far as I can tell. I probe it with my voltage meter and confirm 240V from the generator inlet through the breakers, onward to the charger/inverter’s inputs. Yep. All of it is right. 240V across, 120V each leg to neutral or ground. Perfect. Except nothing’s happening.

Are there any other power-on switches I missed? Doesn’t look like. Should the charger/inverter be totally dark if the batteries aren’t connected? No, it should light up and say “I don’t have batteries” and simply not try to charge what isn’t there. Likewise, since there’s external AC power applied, it wouldn’t try to generate AC from the batteries, either. It should just wake up and say “I’m ready, but honestly, there’s not much I can do for you right now”. But no. It didn’t even wake up enough to notice that much.

I am not delighted.

I have an email in to (different) tech support on that.

Immensely frustrated and a little concerned that somewhere between zero and five things are critically broken right now, I’m gonna just call it quits for today and do something else. I need to step away. And anyhow, I need to get some professional help before proceeding.

Meanwhile, site prep actually is moving forward a little. We’ve got someone lined up to do the site evaluation for the septic system and the shale dump for the access road should be happening in the next week or two. So that’s a little bit of good news on what is otherwise a very disappointing day.