The main reason I got Bob (the tractor) was for snow management. The plow has been great, clearing my road with ease (and comfort, as I sit in the enclosed cab with the heat on and the sound system streaming my favorite Pandora station). The other thing I wanted him for was taking care of the snow mountains that form when the workshop roof sheds a load of heavy, wet snow right in front of the doors.

One might very reasonably ask: why didn’t the company that designed and built this building — per my specifications — notice that the eaves emptied out in front of the doors and say “dude, you sure you want it this way? We live in a snowy climate and you’re gonna get a lot of snow dumped off the roof right there!”. You’d think that a company that’s been doing design/build of these for years would notice something like that and make mention. Or at least make a strong case for snow-arresting features on the roof, if I wasn’t keen to move the doors to a gable end. Something. But no. Okay, then, quite tired of moving literal tons of snow from in front of the garage and people doors, I wanted Bob to be able to help me with this. Hence the bucket loader attachment.

So, what kind of mountains am I talking about. This was a small one from a recent storm. They’ve been much bigger other years/other storms, but this is the one that got a photo.

It’s not so much that it’s high, but that it has necessarily melted just a little for the roof to let it slide off, in which state it compacts mightily as it hits the ground, becoming quite difficult for a shovel to even get purchase, let alone the extreme density making removal grueling work. Hence the bucket loader attachment.

Hey, speaking of attachments and snow management (and vendors being a bit remiss), when I bought the tractor, I also asked for snow chains for enhanced snow traction. My sales guy set me up with some super duty chains for the rear wheels. But this is a 4-wheel-drive machine and the front wheels do the steering. Why didn’t he set me up with front chains, too? This, I’ll never know. Maybe they weren’t actually necessary? Nope, they were. So after having some steering troubles following the first snow storm, I ordered some front chains.

About a week later, I got a call from the distributor: my chains are in, just come in to pay for them and pick ’em up. Great! So I take the 45 minute journey to the tractor place, go to the parts counter, get and pay for my chains, and am on my way. But here’s the thing: the box of chains was shipped to them from their distributor via UPS. Why couldn’t they have taken my money up front and had the chains shipped directly to me — via that same UPS — saving me 100 minutes of time and 2 gallons of gasoline to get there and back? This makes no sense at all and is what I like to call “preventable stupid”.

It was also “fun” installing the front chains in sub-freezing weather, trying to “safely” jack up the tractor to get the chains under and around the wheels (no, driving onto them just didn’t work, I tried that first) without anything slipping off and coming crashing down.

That black thing is a kneeling mat, so at least while I work, I’m not also getting cold, wet knees. Got them installed and they made a huge difference. Excellent. So, about that loader…

Well, the loader did a decent job of moving the snow mountain, but here’s the other thing. The garage door itself is not especially stout. I mean, it’s not nothing, but I knew it wouldn’t resist the available thrust of the tractor pressing against it as I went to scoop up that snow. Originally, I was thinking that I’d be able to remove the mountain by approaching from the side, so there was no pressure on the door at all, but that just didn’t work out logistically. Okay, then, from the front, but gently. I’ve been driving this machine enough that I have some finesse, so I was confident I wouldn’t bash in the door.

I didn’t bash in the door!

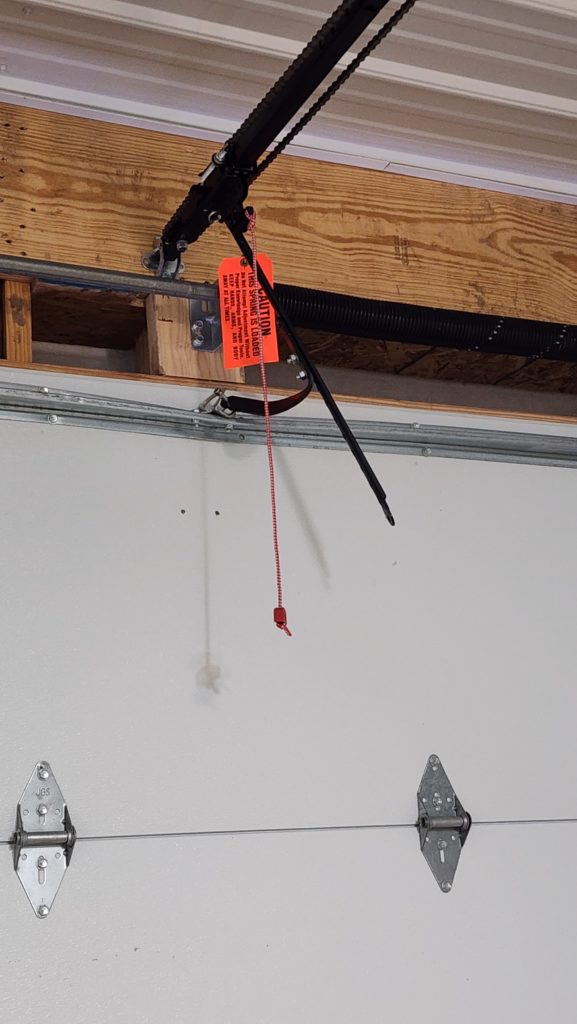

But I did learn that the loader is perfectly capable of lifting the door if it gets caught on the corner of the bucket. That would be fine if the garage door wasn’t rigidly attached to the machine that’s supposed to lift the door. Along with a gouge in the door, this event also managed to rather impressively bend this piece of J-shaped steel.

Straightening this bit of steel was quite challenging. If I had a long piece of iron pipe, I could have gotten some leverage against it held in a vise, but I did not have such a pipe and didn’t fancy spending hours on a special trip to go get one just for this. I improvised. I saw that the bend was mostly limited to one narrow area, so I should be able to at least mostly flatten it out if I squeezed it hard in the jaws of my biggest, baddest vise. So I tried that.

And it mostly worked! I couldn’t get the part close enough to flat, but I got it quite a lot closer to flat. Some good old-fashioned smiting with a 4# hammer with the piece flat against the anvil of the vise was enough to get it sufficiently flat that it would do its job once again.

Linkage re-assembled, door opener tested, all is well. Except that the top bracket on the door itself is still a bit deformed, leaving about a 3/4″ gap at the bottom of the garage door when it is supposed to be closed. I can live with that for now. I may be able to adjust how this J bracket attaches to the opener’s trolley to have it push down a little more. Later. For now, at least, it works well enough.

Lesson learned, though! I now open the garage door before clearing the mountain. And any snow that doesn’t readily get into the loader bucket just by shoving the bucket into it, I assist with a hand shovel. It’s still super heavy, dense snow, but I’m only working with a fraction of it, and only putting it into the bucket, to then drive away and dump at a convenient spot. Far, far, less work for me. That’ll do. I don’t mind some labor and I am quite keen to have access restored to the garage.

The office is heated by a propane heater which is fed by an auto-switch regulator. It will draw from a full tank and ignore an empty tank, allowing uninterrupted service when one of its tanks becomes empty, as long as I fill it before the other thank is also empty. This has been working great for 2.5 winters. On my last tank swap, though, I heard a light hiss.

A whut?

Yeah, that. Gas leak. Okay, maybe I just didn’t tighten the hose to the newly installed full tank. No biggie. Just tighten it a little more. Nope, it’s tight. Not seated right? Unscrew and re-do. Nope, it’s fine. Hiss remains. Oh-oh. Some investigation reveals that the hiss is actually coming from the other side of the regulator. Not the side where I just replaced the tank. The side I didn’t touch at all. Curious! I find that the leak is actually right where the hose enters the regulator. That’s unexpected. Why should it have come loose? No idea. But a loose fitting is easy to remedy. I turn off the gas, grab a wrench, and tighten it a little. Turn the gas back on – the hiss is worse! What?! Further inspection reveals that the fitting isn’t loose. It’s actually cracked and falls off in my hands as I manipulate it. Oh dear.

The pic on the left is the hose end with half the fitting still engaged wit it. The pic on the right is what’s left of the fitting at the regular inlet.

My first thought is that I have a spare regulator with its own fittings. I should be able to just remove this fitting and swap in one from my spare regulator, assuming I can also free the fitting fragment from the hose end. Well, I can’t for the life of me get the broken fitting off the old regulator, so there’s no swapping in a new one there. Okay, plan B is to just swap out the regulator entirely. I mean, that is why I have a spare. It’s almost dark, it’s below freezing, and I am in no mood to be doing gas fitting in the dark of night. Also, I’m not convinced the new regulator’s fittings match the hoses I have, so I think I need some new hoses. In February. It’s not exactly “propane accessories season” (a/k/a backyard grill season), so I’m a little concerned. Time for a shopping trip.

Of two stores tried, it’s Tractor Supply that has propane accessories this time of year. Thanks, TSC!

Bright and early the next morning, at first light, I do the repair, swapping out the old regulator for my spare and install it with the new hoses. This kind of winter work requires some preparation, however. This is the scene just before I get started.

First, tools and parts are in a plastic tub so they won’t get lost or full of snow. Second, the new hoses are going to stiffen up a bunch in the cold. Third, the leak-check fluid (a high-viscosity soap solution, essentially) is going to freeze, rendering it useless. I need to prepare for all of this.

No problem. Hoses I keep inside my winter jacket, where they’ll be nice and warm. The leak solution bottle I stash in a pocket, which while one side is exposed to the ambient temp, the other side is warmed by body heat, which should be sufficient to prevent freezing. It works – the hose remains supple for easy installation and the fluid remains fluid enough to still do its job.

New regulator, new hoses, all good.

Looks about the same, but this one has no leaks!

The propane system wasn’t the only thing to spontaneously fail recently. So, too, the gasket on my wood stove. An easy fix with adhesive I already had on hand (if you’re noticing I have spares/supplies for nearly everything, you’d be right. I also have a spare fresh water pump, gray water pump, 12V power supply — all the stuff that is critical and not readily found in local stores), but a nuisance.

Fortunately, the gasket itself is in decent shape, so I don’t need a new one of those just yet.

The folding wall-chairs I made are pretty great, but they do have a serious hazard. The foot rail is easily dislodged by casual foot placement, resulting in the chair becoming a slide and possible entanglement of the occupant with the foot rail and legs. Don’t ask me how I know. I thought about various ways to secure the foot rail, looking for one that was least obtrusive and easy to use. Although I didn’t fancy drilling more holes in the floor (there are still several from mounting the lifting column that used to serve the table), the best answer was some pegs in the bottom of the rail that engaged with holes in the floor. This readily secures the foot rail and doesn’t require bending down to set some kind of slide bolt. When stowed, however, the pegs are visible. One look at this picture and you’ll know why I call them what I call them.

You’ll also see that the chair deck and back parts aren’t perfectly parallel. This bothers me a bit. I may re-build these chairs in hopes of doing a better job. They were much more challenging to make than I expected. I think the road to success is paved with some carefully built fixtures that will help maintain spacing and position. Loose spacer blocks and clamps was not the right answer. I’ve done a fair bit of construction, but actually precious little furniture building, which is its own discipline distinct from how buildings/structures are made. I’m still very much in the early learning stages of furniture making.

One of the things that makes a home more homey is when space is used well and things have places. I recently built and installed a few small shelves that contributed nicely in this way.

First, this set in the corner of the BeDiLiA. They serve as a night stand/charging station when the bed is down (left) and are decently unobtrustive when the table is down (right) such that it’s no trouble to walk past them for seating.

I can’t tell you why it took me over a year to build a little shelf for this dental care device so it could be easily used in the bathroom, but finally it is done. Until this day, I would carry the thing to the kitchen, where the only flat surface near a place to spit could be found. It wasn’t really such a big deal to do this, but it was a nuisance. Better now.

But not perfect. After a day like this, it became clear that it’s just big enough to encroach on the toilet approach (toilet is to the right of the frame), so I’m going to swap it with the hand towel ring and move the TP holder over a little to make room. This puts the low-profile things in the constricted area and the larger item where there’s more room for it, even if it means using the toothbrush/flosser left handed. I’m okay with that.

Even with the imperfections, having these shelves has made a palpable difference in the order of the house, which I appreciate. Every time I do stuff like this, I really notice how much better the house feels but oddly, when these kinds of projects are pending, it never dawns on me to prioritize them because of their easy benefit.

Recently, I purchased a second chain saw. This one has a short bar – only 10″ – but for good reason. The business end is at the other side of a 9-13′ telescoping pole! When fully extended, even with the included shoulder harness, it’s a bit of a beast to maneuver. And obviously, cutting tree parts that high up presents significant hazard to the lumberjack. I had my helmet and eye protection on and was glad for them. I didn’t get hit with anything, but there was one close call that had me fall to the ground as I slipped in the snow, trying to get out of the way of a branch that went differently than I thought it would. Every time I do tree work, it is abundantly clear why this is called the most dangerous occupation.

It was, however, the perfect tool for clearing these “widow makers” from over my road. I mean, a bucket lift would have been more perfect, but I don’t have one of those (or a place to put one) (or a desire to rent one just for this).

What you can’t see in these frames is that those overhanging branches are coming from trees which are themselves leaning at about that same oblique angle! All that horizontal stuff? That’s not lateral branching. That’s what would otherwise be pointed to the sky!

Quick update on the solar battery saga – now six full weeks since the update that crippled 1/3 of my battery system, I have given up on their so-called “tech support” and recently sent a letter demanding they simply replace it or I would take them to court for having damaged my stuff. I really really don’t want to go there – so much bother and expense – but also I need the full function of my system and they are responsible for its recent failure.

Interestingly, I note that this whole product line is no longer offered for sale (I bought the most recent one only just about a year ago), which for various reasons is worrisome. The company is still in business and selling other stuff, but this whole line is evidently discontinued — or supply chain issues are so bad that they don’t even mention them as being for sale at a future time.

What does this mean for my replacement demand? An excellent question! I would accept some other product that did the same job – even from a different vendor – I don’t really care whose products are holding the energy, only that I have something that does that. I am not optimistic that this ends well, but I will let it play out just a bit longer.