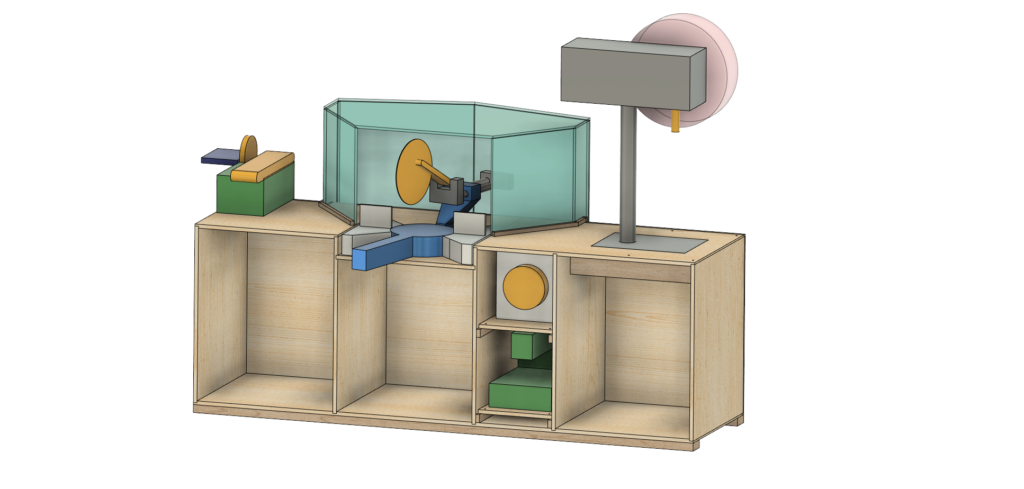

About a month ago, I showed you this rendering of a tool island I meant to build.

I built it. Or, rather, I’ve built much of it. The tool dock shelves are pending, as is the dust collection shroud. But it is coming along nicely.

Already it is helping make space in the workshop and the way the chop saw is placed lets me cut stock up to 8ft long anywhere along its length without having to provide support. The deck of the island automatically does that. The saw is about 54″ from one side, you see, so even a cut at the end of a 96″ piece of wood won’t have more than 42″ hanging over, which is less than half (48), so the board will stay put as a consequence of its own weight and balance. This, of course, was the whole point.

If the whole shop seems less cluttered and more open, that’s because it is. The jointer now has a home (just past the island to the left) which has air space clearance of at least 8ft fore and aft for easily processing stock.

The new band saw (not yet purchased) will go where that last stack of boxes is, behind the island. The last machine will be a decent sized lathe, for which there isn’t yet a room, but there is a designated place. It will go just to the right of this scene, against the partition wall that separates the shop from the garage. When all of this is the way it needs to be, I’ll do a walk-through video and this will all make a bunch more sense.

If you remember way back, there have been a handful of problems running my 3HP table saw on my solar power system. First, the AC inverter couldn’t even run it. Then I got a much bigger inverter (4x the peak power of the first one) which could run it just fine, but had a lot of trouble starting it. The motor draws over 6x its nominal power for the first moments of starting and that is enough to really upset the inverter. I found a silly dance that made it just barely work: turn on the dust collector, let it spin up, then turn it off and immediately start the table saw. The inverter, when it’s delivering power, also has some reserves at its output stage, but only when it’s running under load. But those reserves aren’t enough to start the saw if the dust collector is running, but immediately after turning the collector off, the reserves are still there, and in combination with the base ability to supply power, the inverter can start the saw. Just barely. And then I can turn the dust collector back on, because it doesn’t need such heavy starting support, then actually use the tools.

It worked, but required careful coordination and of course was the wrong kind of silly.

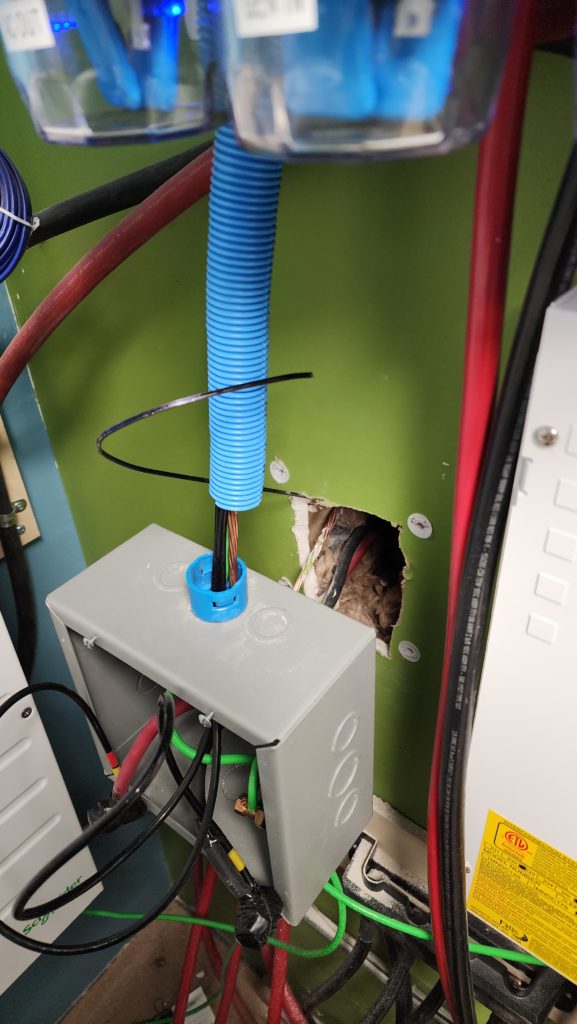

Recently, I finally found a device that could “soft start” the table saw motor. Basically, it’s an external throttle that prevents the heavy starting load from being seen by the power supply. Instead, it simply limits the flow of power into the motor, gradually ramping it up, and in the process, getting the motor started for real but keeping the power supply from being leaned on too much. Most soft-start devices are for 3-phase motors and this is a 1-phase motor. Most soft-starts for 1-phase motors are for smaller ones than this motor. And all but one have complex circuitry requirements that made them unsuitable for this application. But there is the one. Just the one. But I only need one. It arrived today and I installed it.

Presto, one little tan box and a few more wires. For the curious, the device is the Schneider ATS01N125FT. I’ve only used it for a few starts to get it dialed in, but it seems to do the trick nicely. And I can even power on the dust collector first, if I want.

Now I just need somewhere to hang those wrenches whose hook I had to remove…

I’ve been having some performance issues with my WiFi mesh — formerly a Netgear Orbi system, which I then replaced with a TP-Link Deco system. The Deco is doing better, but the link between the workshop and the house has always been challenging. I’m not really sure why, honestly. The relay is in the middle of a big window and it’s not even 100 ft with decent line-of-sight between points. This should be easy for WiFi. But then, the workshop is a big metal building and maybe just being a big metal plane so close to the relay device is confounding its radio. Okay, then, how about another solution?

Well, there are outdoor-ready mesh relay nodes. That would be great – put the relay outside, some distance from the workshop’s big metalness. That should improve connectivity to the house (not metal – lots of wood) and improve signal out on the grounds for mobile devices and my security cameras. Cool. And the perfect place for it? One of the vertical poles under the solar array! There’s even conduit from the office (where the network router is) out to the array. Perfect! Just run a cable through the conduit and set up the outdoor relay on the pole. Piece of cake.

Well, almost.

One end of the conduit terminates rather obviously at the junction box under the solar array. That’s easy. The other end terminates kind of randomly in the wall in the office. Why? Well, there were practical reasons why having it terminate in a box was going to be difficult, given the order of construction of the office, and anyway, it didn’t matter much because really, what else would I possibly want in that conduit except what was there in the first place: the heavy cables from the array to the office power center? Making it easy to run another thing through that conduit didn’t enter my mind. So while I could thread a fish tape (that’s what they call those semi-rigid things that you push through conduit, attach your wires to, then use to pull the wires back through) from the junction box outside all the way to the office, I actually don’t know where it would emerge exactly! I can identify a 16 inch span of wall width where I know it has to be, but how high? Not known. How deep in the 12″ thick walls? Unknown. It would be easy for the end of the fish tape to hide behind some insulation and never be seen. Not without opening up the wall a bunch. And that wall has all my power system stuff on it. And it’s obscured by my battery bank, too. It’s a big deal to try to find something in there.

What about trying to send the fish in from the office side of things? I know exactly where it would come out (the junction box at the solar array). But the same problem exists for finding the entrance of the conduit, somewhere in the wall.

I don’t know why I thought finding the entrance would be easier or somehow better than sending the fish in from the array box — although the office was warm and the outside was cold, so maybe that was it!

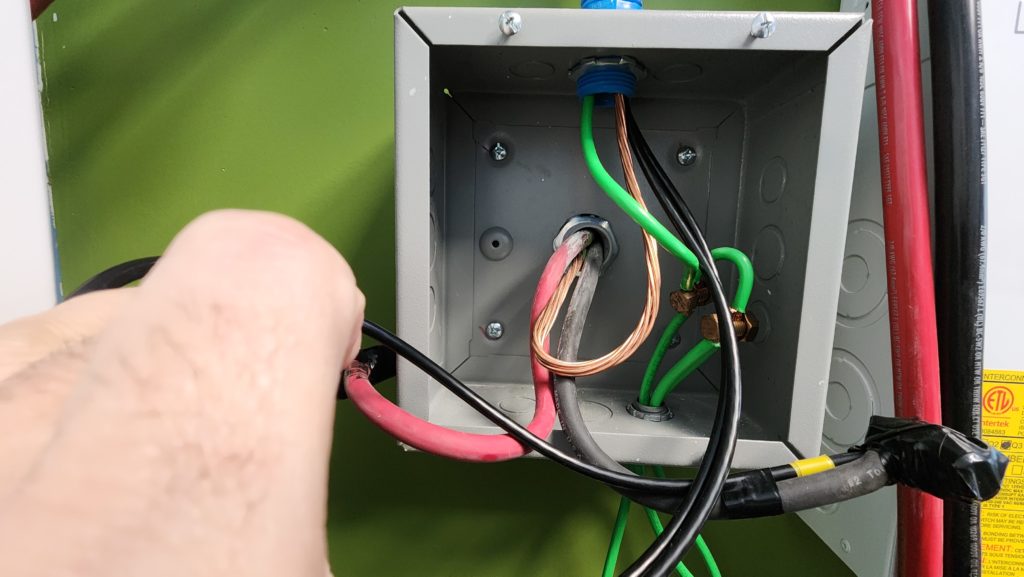

The heavy black and red cables came from the conduit, into this junction box in the office. If I take the box off the wall, maybe I can actually find that conduit entrance? Maybe?

Well, not through that little hole!

I did have an idea, though! What if I loosely tie the end of the fish (thin black) to one of the wires, then feed it in? Would the tie slide along the cable and guide the fish into the conduit? Hm? Can it be that easy?

No. It can’t.

The cable is stapled to the framing, in the wall, so the tie would get hung up there. If it even moved, which it didn’t, because the cable jacket was too rubbery and arrested the whole thing before it got anywhere. Crap.

Okay – this junction box is pretty big. I could open up a fair bit of wall behind it and maybe get my hand in there to feel around for the conduit. I wouldn’t have to repair the wall — the box would cover it!

It seemed like a good idea. I even thought I found the conduit! I sent the fish tape in and kept feeding it and feeding it . . . but it did not emerge at the far end, after the 140 ft or so away I knew it to be. Hm. Maybe I missed and the fish was just coiling up in the wall somewhere I couldn’t identify. Maybe it slid behind a post and the exterior siding and was accumulating in an adjacent wall area? I went to pull it all out and it quickly got stuck. No getting it back. I had to cut the fish and leave it, wherever it was, for whomever it is that remodels or demolishes this area some time in the future to find and remark, “poor bastard, I know how this happened”. There’s like 100ft of it in the wall somewhere.

Okay. Maybe sending in the fish from outside is the answer. Now that this big hole exists, I can probably reach around and find the fish if it actually comes through. It’s still pretty awkward – the hole isn’t really bigger than the thickness of my arms and as you can see, it’s crowded nearby. But maybe?

I go outside and send it through. The fish is marked so you know how much you’ve paid out. I got close to that 140ft I expected to send, then it stops abruptly. Ram. Ram. Ram. Doesn’t budge. Ram some more. Nope. Pull it back, send it in again. Same wall. I have no idea what it’s hitting — and there’s no way to look — but I’m definitely not getting through. Maybe its actually the end of the conduit where the cables turn and come forward, cutting off the fish as it tries to emerge? Without being able to actually see the conduit end, nor find it with my hand (too deep in the wall/arm too big), I can’t make a plan to address it.

So, what next? Well, if I’m willing to commit to dismounting some equipment and repairing the wall, I can just cut into the wall big enough to see what’s going on and have room to access and ideally correct it. While I’m there, maybe extend the conduit properly forward to the wall surface so if I ever want to send something else in there again, I have definite access end-to-end. That makes some sense. I really hate wallboard work, though. And repairs are even harder to make look nice. All the moreso in a crowded space.

Hm. A friend has a bore scope (a video camera on a stalk) that he will be bringing by soon that we can use, hopefully, to inspect the area and maybe learn something before committing to destructive investigations. Stay tuned.

Flue?

Flue.

Good news?

Good news.

It snowed.

Not a lot, but some.

And the glacier break clearly did its intended job, sending snow to either side of the flue.

This early-morning pic shows some snow riding up on the breaker, as well as the edges being sheared off as I meant for it to do. It’s more ride-up than I expected, but this is also a shallow snow. I’ll be interested to see what it does when the snow is deeper/heavier. But even if it does ride up the break, it will impact the flue stack right where there is bracing and the flue is round and smooth, so at that point, the snow should just flow around it if it gets that far. That’s the idea, anyhow. When there’s a heavy snow, we’ll find out!

Speaking of snow, for the most part, the solar array sheds snow on its own. . . or I brush it off with a soft-bristle broom on an extension pole. This works great. Except when there’s an inch of snow followed by ice. When that happens, the snow is captured on the panels. If it’s cold and gray after that, it just stays there. I can’t safely break the ice and the snow does an outstanding job of reflecting the sunshine so the panels harvest no energy.

Below: panels with snow brushed off, but only down to the ice, beneath which was more snow!

Below, a little corner of ice broken through, so you can see the layering of ice over snow.

It was like this for a week. I ran out of energy and had to use the generator to recharge my batteries. Fortunately, a sunny and warm-ish day did eventually arrive and that softened the ice just enough that my long-reach broom could break it up just by sweeping over it. And so it was.

The panels actually have active elements on their back faces as well, to capture sun reflected off the snow. That only works when it’s bright out, which it wasn’t. Had it been, that reflected sun might have warmed the panels enough from behind to melt the ice on the front. But no. Cold and gray for many days it was. Essentially zero energy from the panels that whole time. This, of course, is why I have the generator, but I’d much rather have the sunshine! Not just to avoid burning fossil fuel in the generator, but also because bright days are far more cheery.

Following up with the fish story – my friend came by with the bore scope and we attempted to inspect the inside of the wall approximately where the conduit was expected to be. What we learned was that the end of the conduit is indeed plugged with something intentionally, which explains why I couldn’t get the fish through, and that the end of the conduit is quite a bit deeper into the wall and closer to the floor than I thought.

If I want to actually access it, I’m going to have to break into the wall a fair amount, in a cramped space. I think it can be done, but it can’t be done neatly or easily and I’ll definitely have to repair a section of wall. Joy. So. Much. Joy.

The question is, then, do I really want to mount that wifi repeater at the solar array that much that it’s worth the trouble to dig into the wall like that and then make repairs after? Maybe? That location really seems ideal in so many ways and using the conduit makes so much sense, if only I could access it. The right thing to do would be to open the wall enough to actually get my hands on the end of the conduit, extend the conduit properly up and out to a junction box, so that there is no need to stuff a plug in the end and such that there is an easy way in and out. And as long as I’m pulling the ethernet cable through, I should pull a string through, too, which I can use later to pull whatever else comes to mind later. I didn’t think that was going to be anything when I installed the cable in the conduit and I’m paying the price for that oversight now!