Just over three months of residence and here’s what I know about all the things. Living in a 162sf house is no problem. Living a modest life on solar power and well water, also no problem. Living where I can go days without seeing other humans – unless I want to – is no problem. Now with satisfactory internet service, working in a 100sf office space in the woods, no problem. Moving from 50 years of suburban living to a fairly rural location, no problem. I like the self-reliance. I like the low population density. I like the dark, dark nights. I like the quiet. I am just close enough to necessities that it’s not a hardship to get food, do laundry, etc. If I need to go into The City for a Big Hardware Store or some other franchise outlet, it’s a bit of a big deal, but only a bit of one. I’m there in less than an hour. So no just zipping out to get a bag of cable ties from the local store at 8pm on a Sunday, but with a little planning and a little patience, I can get what I need. No problem. The people are friendly and neighborly. I routinely get random offers of help and suggestions to solve any problem I may speak about in public. Lovely. It does get cold here — minus 8F the lowest I’ve measured so far — but honestly, that’s no problem, either. I’m prepared and plenty cozy. It doesn’t take much to heat a little house like this. So far, so good.

What turns out to have been the most difficult thing isn’t really related to the character or location of the place at all, but simply that the road I’m on is newly recognized by the state as being a road and is not yet recognized as being a road by nearly everyone else. That’s made getting deliveries and anything else address-related (which is more things than you might think at first) very difficult, though slowly I have been able to resolve that, as well. For sure the biggest trouble of it all, though.

I was already working remotely due to C19, so that’s not really a change for me, either. Just doing my thing 200 miles from my old office instead of 20. It doesn’t really make much difference at all.

Even without my workshop operational, I have plenty to do to maintain (and continue to build) the homestead — I’m not the slightest bit bored. I’m not lonely, either. I reach out to my friends by phone and other means. I am starting to get to know some local people, too. That’s very slow going because it’s winter and there aren’t many opportunities to mix and mingle, but slowly that, too, happens. I am beginning to feel at home here. This isn’t just some experiment. This is what I’m doing. And if starting that in the winter and getting this far without totally flipping out is any indication, it seems likely I’m going to stay a while. Good thing, too, considering the investment of time, money, and effort, which have all been quite significant!

Recently, there was an ice storm. Ice isn’t good for pretty much anything – except being pretty, which it’s pretty good at. I was disappointed that even my digital camera, which while by no stretch is any kind of professional grade is nevertheless some respectably sophisticated apparatus, could not come close to capturing the splendor of it. Just not enough dynamic range to get a decent exposure that showed what was here. Maybe it’s my picture-taking skill, maybe it’s the camera’s fundamental limits. Hard to know – I think I know what I’m doing when taking pics, but perhaps there are things to know about ice photography that I do not know. In any case, it sure was pretty. Here’s a little bit of that, shown at no more than 10% as magnificent as it was in person.

One thing about the ice that wasn’t beautiful was how thoroughly it coated my solar array! It wasn’t even a nice glaze like on the trees. It was all pebbly and quite effective at catching little bits of snow, making it essentially impossible to clear off. One does not use a scraper on solar panels (scratching the glass will make it fail, or at least impede solar harvest). This was as clean as I could get it with a broom.

However, that seems to have been enough! By midday, enough sun had made it to the surface of the panels to heat them up enough to get the defrosting process moving right along, even as air temps were still below freezing.

I was pleased. By the end of the day, they were basically all clear.

As they will, trees, especially young ones, bent under the weight of the ice. For the most part, I am content to let them be trees and bend as they will, but this one needed to be trimmed so I could actually leave the property without damage to my vehicle. I just had to trim a bit off the end and that was enough to have it spring up and out of the way.

Remember a little bit ago when I noticed the faces in the power outlets? The ability of the human mind to recognize faces is deep and well-known to science. It’s still fun to see them in unusual places, though, like the back of this electrical box or the rear cover of the generator.

And then there was this little creature formed by a fun curl of facing paper on the wallboard….

Last installment I wrote that I had installed a temporary 240V outlet so I could start using my table saw, at long last. Since then, I made some room in the workshop area for the machine itself (which takes a fair bit of volume – it’s a big machine) and wheeled it in there. Okay! Time to start making some shelves and other things more easily. Excellent. I’m so ready. I plug in the saw, start it up, and… no. It won’t go. It turns out my power system can’t supply the heavy starting power it requires. It doesn’t struggle, it just gives up. It starts to start and then halts immediately, but not without making the lights flicker and otherwise making some unseemly sounds. Crap. Interestingly, it does not actually trip the overload protection on the power center. I’m guessing the saw starts the motor, sees the deep sag in the power, and cuts itself out of the circuit before the power center decides it’s having an overload at all. It’s nice that the lights didn’t go out (as they would if the power center cut off due to overload) but it’s not nice that I can’t run the saw.

I tried the dust collector and it was worse. It did trip the overload. Okay, I’ve got a problem. The first question is just exactly how big a problem do I have? I need to know the running and starting currents required by these devices so I can see about finding another inverter that’s got the gusto to meet their demands. That starts with this:

That device can measure AC current – including “inrush” current, the spike that some devices exhibit as they’re getting started. It can only measure current if the supply wire is isolated and passed through its loop, though — can’t just run the whole cord through it, since that cord is carrying current into and out of the machine, effectively making the net current seen by the loop zero! No problem. I built this little fixture to split out all the wires for test. It’s nothing more than a plug and a socket, with all the individual wires accessible. I can pass any one of them through the meter’s loop for measurement.

I ran both machines directly off my generator for observation. I found that the running current of the two pieces of equipment (without any loading), was about 4A and 7A at 240V. Totally reasonable. The inrush current, though, was through the roof. The table saw registered 87A and the dust collector was 52A. Now, the inrush measurement is very brief – 100ms – and given the physics of it, if voltage were held by the inverter but current was limited to the inverter’s maximum for that brief period, I would expect the motors to start just fine, though perhaps a little slower than when on utility power. I mean, my generator is rated for maximum 7500W (240V at ~30A) and no way is it providing 87A for more than the very tiniest impulse – the energy just isn’t there to give. So while the device may have drawn an 87A spike, and my instrument was sensitive enough to catch it, I believe it is physically impossible for it to be drawing that kind of current for more than half an AC cycle (8ms) because the generator simply can’t supply it. Thus, I’d expect an inverter to handle this pretty well, especially the one I’m looking at for this, which boasts of preventing voltage sag in the face of instantaneous overload. “Unlike many other inverters, the Conext XW Pro helps stop voltage from sagging dramatically during surge conditions. The Conext XW Pro handles surges of over twice its rated output power with only a minimal drop in output voltage for limited periods of time.” – (Owner’s manual, p27, “Surge Performance”). In point of fact, this 7500W generator started each of these devices just fine – suggesting that the 12000W surge capacity of that inverter would be totally up to the task of starting them (just a few seconds), as long as it didn’t sag too much to get the motor controllers upset. It sure seems promising, but I’d hate to be out the $3500 cost if it turned out not to work…

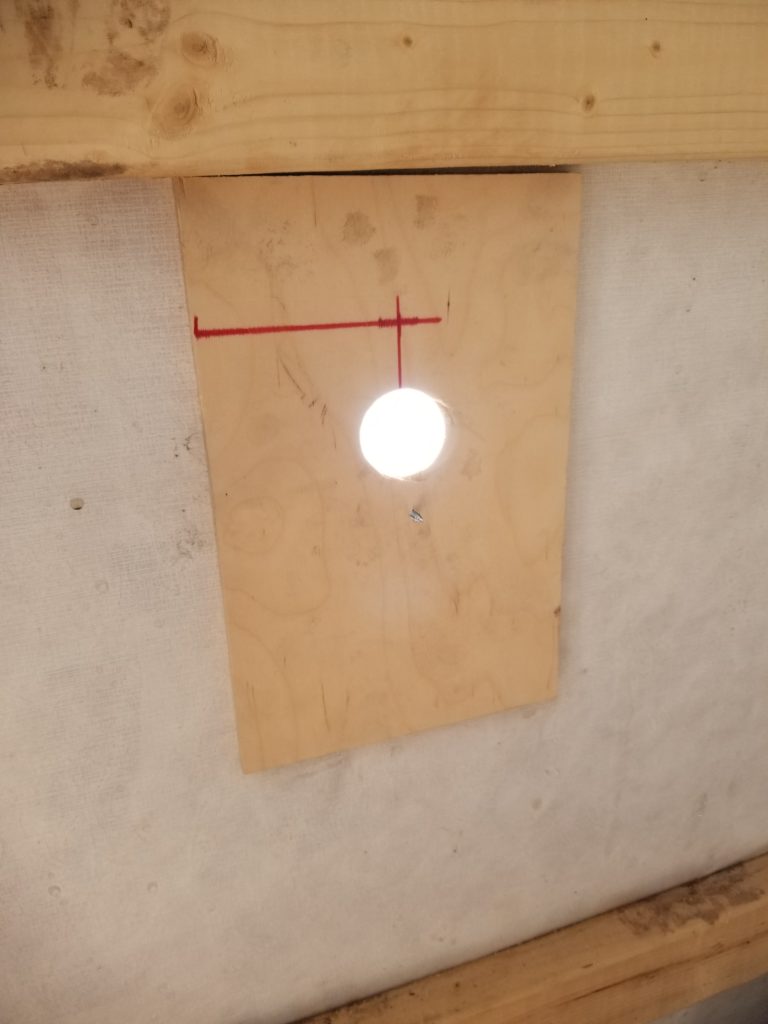

And hey, speaking of generator power, I really wanted to close up the ceiling in the office. The only thing keeping me from doing that was there remained one pending electrical run from the power center: the generator line. So I picked a spot on the outside of the W.O.G. for the generator inlet box, drilled a hole, made a backer board (because the walls of the W.O.G. are sheet metal and not really up to holding anything securely on their own), and then went to install the generator box.

Only to realize that I did it again: I misjudged the location of the hole and drilled it exactly at the wrong place – over a big rib in the siding. I can span those shallow ribs okay, but the big rib is big and I can’t mount a box over it. Crap. I don’t have any color-matched and profile-matched metal to make an invisible patch, so I’m going to have to just wing it. This is especially sad because this is right in the front of the building, where I will see my error every day. But so be it. Now I need to figure out how to plug a hole in some sheet metal without any metal. The answer? Some pressure treated wood behind it and some silicone to seal it. Not elegant, but effective. Okay, I can do that.

Silicone sealant was applied afterward, to fill the gap and keep out the weather. The question is… how did I hold the wood there to screw it in? I mean, there’s nothing on the other side that would hold it in place — including a helper; I don’t have a helper and it was challenging to put some kind of brace there — I tried that. Then I had this idea: give the wood a handle! So I drove a screw in just enough to get purchase and used that as a handle to hold the block against the back of the siding while I drove sharp-point screws from the front to cinch it up.

That’s why there’s a little shallow hole in the center of the block in the previous picture 🙂

And then on with drilling a new hole, located so the box does not encounter any big ribs. There was a backer board for the box, too, which had the same problem of nobody and nothing to hold it in place while I tried to secure it to the metal from the outside. This time, though, I had a hole (for the wires to pass) and I also had a finger. That was all I needed to hold the backer board in place to drive the first two screws.

Because the box will see a heavy generator cord plugged and un-plugged from it, the backer board is required to stiffen the sheet metal and provide some stability to the box mounted on the other side. It also provides something in which the screws in the box can get some purchase. The thin sheet metal would definitely be insufficient and using nuts-and-bolts would be quite difficult because of the nobody-to-hold-it-on-the-other-side problem. A simple board will get it done, and did.

And now there’s a place to hook up the generator to the W.O.G. if/when needs be.

I haven’t actually tested it. I should, though I’m also not the slightest bit concerned. I’ve installed these kinds of boxes many times and I checked the wiring on this one a few times at both ends. It’ll be fine. This had already been installed when doing the on-generator tests for the saw and dust collector (connected directly, not via this box). Why I didn’t also test the inlet here, as well, I do not know. Fixated on the other stuff, I suppose.