Okay! Block-and-tackle is here, time to raise the power center up to the Storage/Utility Loft. Gather rope. Rig the daylights out of it. Hoist.

But before that can be done, something else must first be done: mount an anchor in the ceiling that can take a coupla hundred pounds. The douglas fir 2×6 rafters should have no problem bearing that at all, but the trick is to (a) know where they are, now that the ceiling is covered, and (b) sink an anchor such that it holds and doesn’t split the wood. So I do that first. A nice long eye bolt in a carefully pre-drilled hole should do it. To be sure, I suspend myself from the eye bolt (at very low altitude, in case it fails). The 245# load test passes. I am confident I can raise the 120# power center without incident and so up it goes.

This, as it turns out, was the easiest part of the day. The power center is gently raised to the SUL deck level. Landing it there is a little tricksy, as I have to ease up on the rope a little, effectively giving the rigging more slack, so I can push it securely onto the deck. Not a big deal, but a little bit of finesse is required since I don’t have a helper today. I’m on a ladder, hoist rope in one hand, guiding this 120# behemoth onto the deck with the other as I slowly let up on the rope to give me some slack to make it possible. And do my best not to fall.

Okay, it’s up! So far, so good. Next stop, installing the mounting plate. A few measurements, double check with the level, zoop! Done! The next question is how to get this 120# monster up on that plate. There’s just about 3ft of headroom here, so it’s cramped. The pipe heads of the gray water tank are in the way. There’s no way I can lift 120# at arm’s length in front of me at this angle. I can’t get my legs under me or it to do a safe power lift. Add to the complication those three bulbous things on the bottom (clear plastic with blue stuff inside), which are not exactly delicate but I can’t lift by them or have them bear significant weight at any time. The back plate makes this all a bit harder because the bottom of the plate is a narrow 1/8″ edge of steel. I can’t safely land the power center on that – it’ll just tip over. I can’t grab by that, it’ll dig painfully into my hands, even with gloves (nevermind the angle issues).

What to do? I have an idea: slowly shim it up, left and right, until it’s the proper height, then just shove it onto the mounting bracket. Piece of cake!

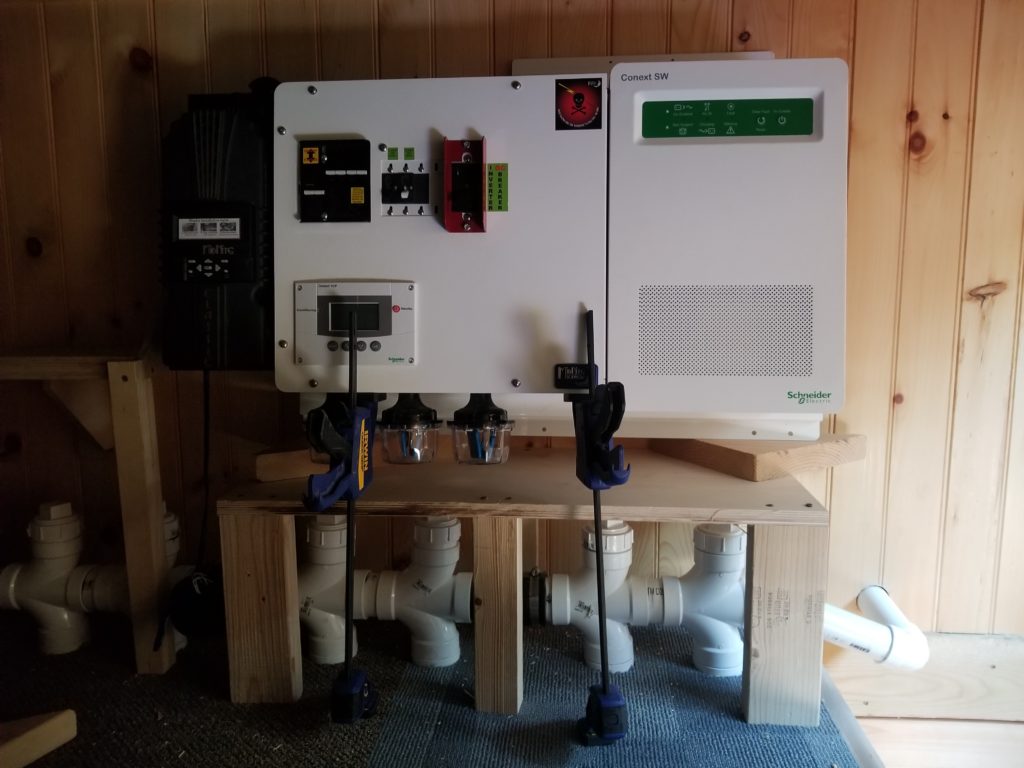

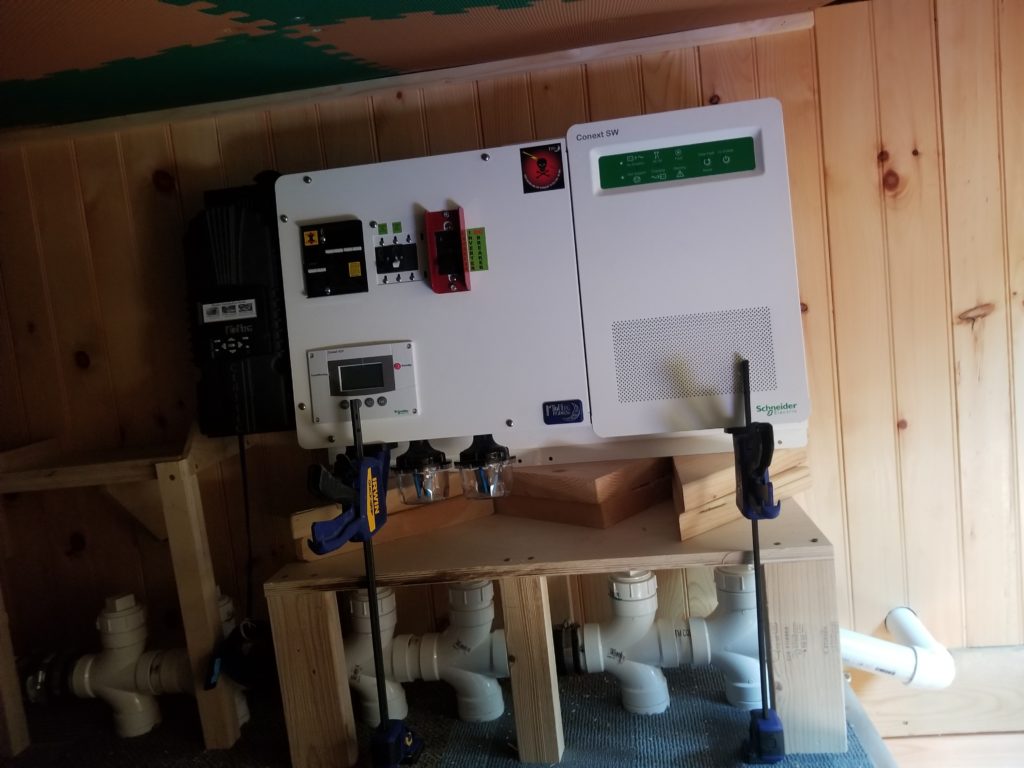

I get stared with the shimming technique. I remember that my 24″ quick-grip clamps can be reversed and act as power spreaders. Perfect! I can use them to lift — and hold — the weight of the power center while I wrangle the shims. “Shims” in this case are blocks of 2x lumber. They’ll take the bottom edge of the back plate (seen here with a few small holes drilled in it) without complaint. So far, so good. 3″ up.

Keep going. 4.5″ up. It’s a little shaky, but I can still control it. You can really see the clamps in spreader mode here.

At 7.5″ up, this is getting a bit unstable. You can see I’m closing in on the mounting plate, though, maybe another 3 or 4″ to go. I think I can make it!

Have you ever played Jenga?

There comes a point at which even a nicely stacked stack of blocks ceases to be stable, even if you don’t take turns removing pieces.

The power center falls.

It falls onto the pipe heads.

I worry that I may have cracked something invisible in the graywater tank. That tank which is inside the floor of the SUL which can no longer be reached or inspected without destroying parts of the house already built. The good (?) news is that I had metal pipe hanger straps at the ends as well as in the middle of the runs, so there was support more or less directly along the line of fire here. Also, that 4″ PVC pipe is really tough stuff. The fact that the power center landed across a few of the pipe heads, I think all at once, so they got to share the load/impact. Honestly, though I fret, I think it’s fine. There’s nothing I can do about it if I’m wrong. I will fill the tank and let it sit a bit, monitoring the level and checking for leaks, though… later. I need to know, even if there’s nothing I can do about it.

I also worry a bit that something vital may have come loose in the power center itself. That would be a Real Problem, given the voltages and especially the currents involved. I will be sure to open it up and inspect all the things. Maybe go at the connections with a torque wrench (do I have a torque wrench?) to be sure.

I still need to get the power center on the wall, though. Having a helper would probably help, but honestly, where would they stand/sit? I certainly wouldn’t want them up on a ladder, extending their reach into the loft as they tried to help lift the power center. No way. That’s asking for a fall. Two people in the loft? Not enough room to be side-by-side here. This is a two person job in a 1/2-person space. Time for a new idea.

Well, the first thing I need to do is not whack the pipe heads again. I built this platform which is strong enough for me to stand on, to protect them and to give the power center a higher place to start. I can finagle it up this high, with a combination of brute force and poor technique.

I still need to lift it higher, though.

Back to the shim technique, though now instead of a huge Jenga game, I have this stout platform on which to start which lets me lean the power center against the wall (more stable) and won’t require nearly as tall a stack of shim blocks to achieve the target height. Those spreader “clamps” are working overtime, but they can handle it. Good thing I put low pile carpet in the loft floor. The clamps can dig into it and stay fairly well put. Still, there’s no good place on the power center to lift by in the front, though I have to lift it at least in part from the front. I do the best I can with what I got and try not to bear too much weight on the front for too long at a time.

3″ up – but that’s 3″ up from a platform that’s already 10.75″ from the deck. Two shim blocks instead of what would have been nine starting from the floor level. It takes just about another inch or so to get it done. I finish with three half inch plywood shims instead of trying to raise it 1.5″ at once for another big block. Gently, gently. This thing is heavy and wants to slide once I lift one side up to get a new shim in… and if it slides, it falls, and if it falls, that’s about $4,000 worth of debris it will make, plus whatever it takes out with it. I do not want it to fall. The spreader clamps naturally fall away as I lift one side, though. This isn’t a big deal until I want to lift the other side, for which I would want that other clamp, now 7′ down on the first floor. This happens several times during the whole process, until I refine my technique to carefully increment the spreaders in rounds rather than in sequence. That helps a lot and saves me from having to try to stabilize the power center, rush (but not too fast) down the ladder, fetch the fallen clamp, pray to all things pray-to-able that the power center stays put while I’m away, then rush (but not too fast) back up the ladder, install the spreader, and breathe out.

Oh, speaking of breathing, it’s hot up there in the loft. Stuffy, too. As well as cramped. I’m fatigued from all this heavy lifting at bad angles, too. I’m aware enough to notice this and take breaks now and then where it’s cooler and the air is fresh. But I don’t want to leave the precariously perched power center alone for long, so I don’t dawdle.

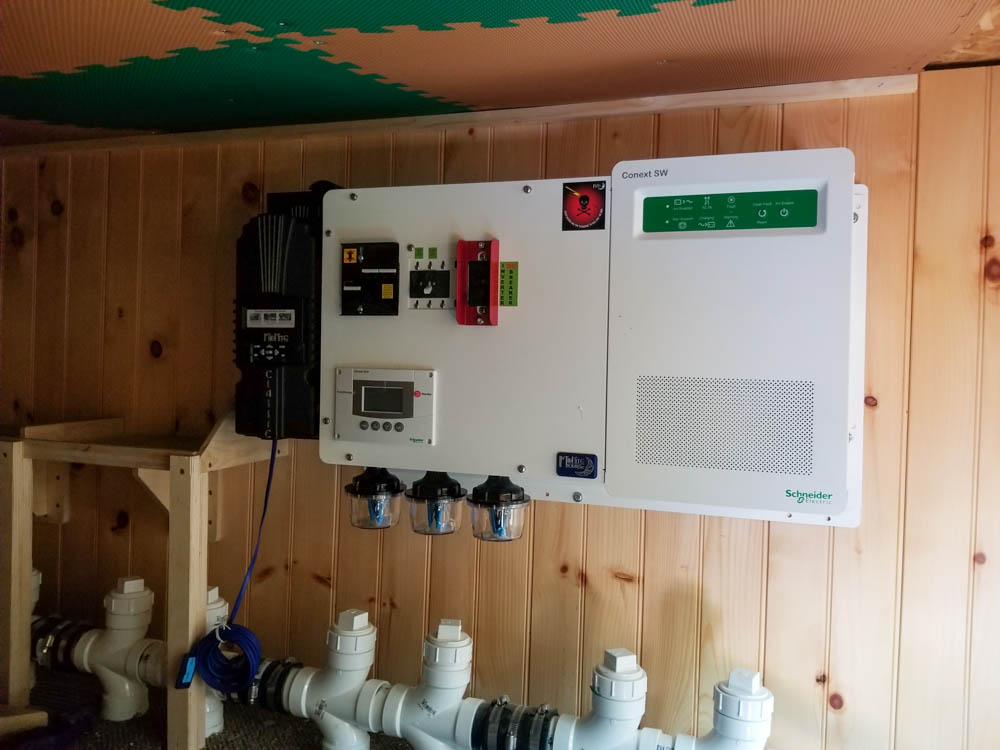

Holy shit, it’s up. It only took what, 2.5 hours? My body aches, I’m sweaty and fatigued, but it’s up. How up is up? Let me remind you:

That far up is up. The loft deck is approximately 7ft from the lower level.

It is done. And so am I.