Outside of the scope of this photo-journal, I made a call for artists to paint a whimsical mural on my tiny house’s bathroom ceiling. At first I figured they’d have to come on site to do it. Then, one of the candidate artists asked if I was going to supply him with boards to paint on, at his studio (and his convenience), to then bring to me, finished. Brilliant idea! Yes! Let’s do that!

First, though, I need to fabricate the boards.

Before that, though (before anything may be done, something else must first be done — is there an echo in here?), I need to make a template of the ceiling so I can accommodate all the not-quite-squareness and the locations of the drain manifold of the in-ceiling graywater tank (shown).

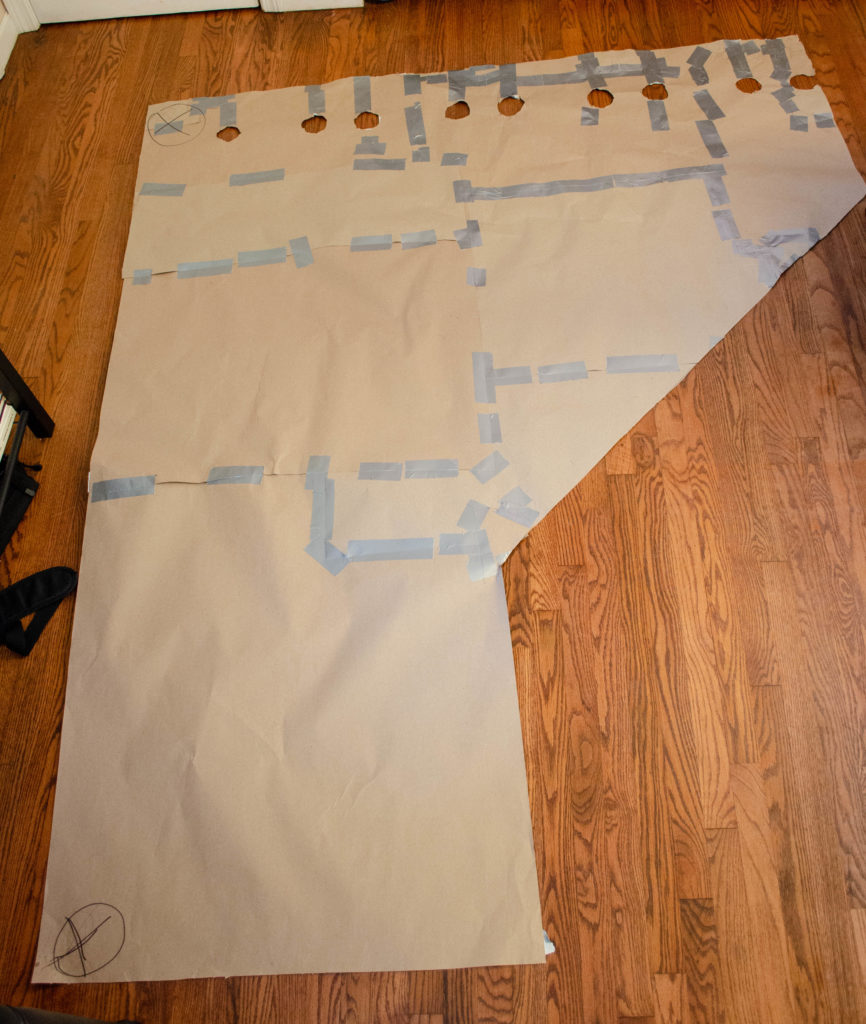

Okay then! I have some left over roofing paper. I tried using that. Too heavy, too buky, not foldy enough. Second try: kraft paper. This worked much better. It was still quite challenging to negotiate around the pipes and overhead work is never fun, but I got it done. Like pretty much everything else, it was slow going and further from perfect than I would rather.

The whole template. Next stop: home center to buy some plywood.

It turns out that because everything is so space-constrained that I had to divide the ceiling into FIVE pieces to accommodate both full coverage AND being able to maneuver them in close, oddly-shaped quarters.

It turns out that one of the pipe holes spans two of those boards. The question arises: how to cut a hole that’s really half a hole? There’s no there there.

Obviously I found a way, since I’m showing this to you already done 🙃

The answer is on the next picture.

You may disregard the misalignment of the pencil mark and the cut hole. The first pencil marks were traced around the roughly cut hole in the template. The second pencil marks were traced (using a thick carpenter’s pencil) around a circle form placed on what appeared to be the centroid of the rough marks. Lastly, the hole was cut according to what seemed like the most correct position, taking all of this into account.

The first part of the answer to “how do I cut half a hole?” is to put some there there, so there’s a full face of wood for the hole saw to engage. That’s the side car — a scrap to make the hole saw think it’s not falling off the edge of anything.

The second part of the answer is to put some there behind there, so the pilot drill for the hole saw has something solid to go through and to support the side car I positioned for the benefit of the hole saw proper.

To check that all five panels fit and could be maneuvered into place, I had to fit them and maneuver them into place (and hold them there) — every one. Well, I started with FOUR panels and the fourth one I couldn’t even get into the bathroom because it was 2 inches longer than the best diagonal route I could find, so that piece turned into two and now there are five boards. And I know they fit because I fit them.

They are considerably less perfect than I hoped although they are about as imperfect as I expected. The thing with having not-quite square spaces is that you can’t cut things to go in them with tools like table saws. This means hand-cutting the boards which means inaccuracies in following the line, which means even more “naturalizing” of the shape.

So okay, there are some seams that aren’t perfectly flush. I will have to instruct the artist not to cross the seams (something about the sleeping habits of dogs and cats, mass hysteria, that kind of thing…) with any important bits of art. Solid colors or any work they want to touch up once the mural boards are in place, great. But if they are going to hand me the boards as done, then I’m going to have to put some filler in the seams and paint over that with some simple solid color. Ideally, this won’t impinge on the art. Hence the not crossing the seams, pet preferences and epidemic madness notwithstanding.

And hey, you can see there’s a finished floor in the bathroom! Yep, that happened. Ordinarily, the floor would be the last thing one does in a room such that it is spared the insults of wall and ceiling finish activites (to name a few). However, because of how close everything is and how it all fits together, the floor has to go in sooner rather than later so I can work on the built-ins and other stuff that depends on knowing the true height of the floor.