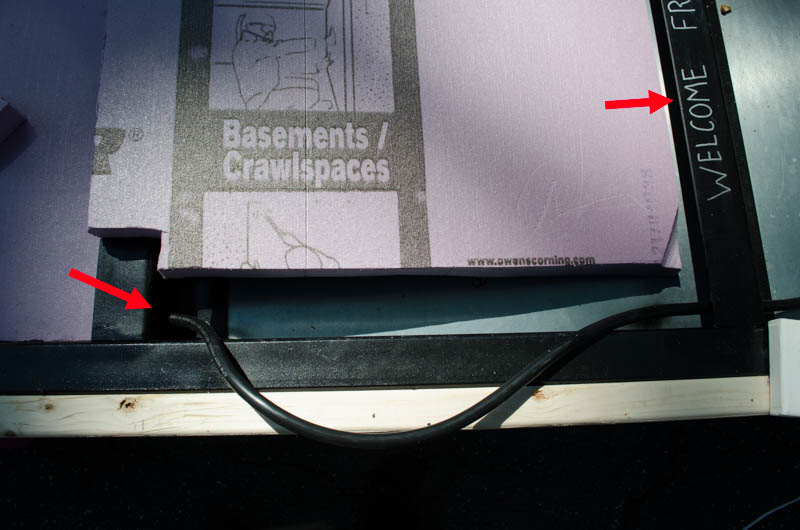

Installing the XPS foam has proven to require more critical thinking than at first you (and I) might imagine. To wit: how does one slide a 54″ long sheet simultaneously under a cable (red arrow, left) and under a lip (red arrow, right), after realizing that once it is flat enough to slide under the cable, it is actually locked in place by the ends of many screws coming up from the bottom, none of which you (or I) wish to trim off, for various reasons.

Solution: cut a notch such that the cable can be dressed over the foam without the foam having to be flat (low) enough to slide under it at its fixed points (left arrow and similarly at right, unmarked), then shove it under the lip. This does leave a hole in the vicinity of the left red arrow. This is also not an actual problem: take the piece removed from that corner, cut it again in two, shove the small bits one at a time under the cable to fill the void. Done.

Not hard to do, really, but definitely more work than first meets the eye for this job. There were many such small challenges, all variations on the theme of how to get under more than one thing at a time when the act of positioning beneath one of them prevents further positioning.

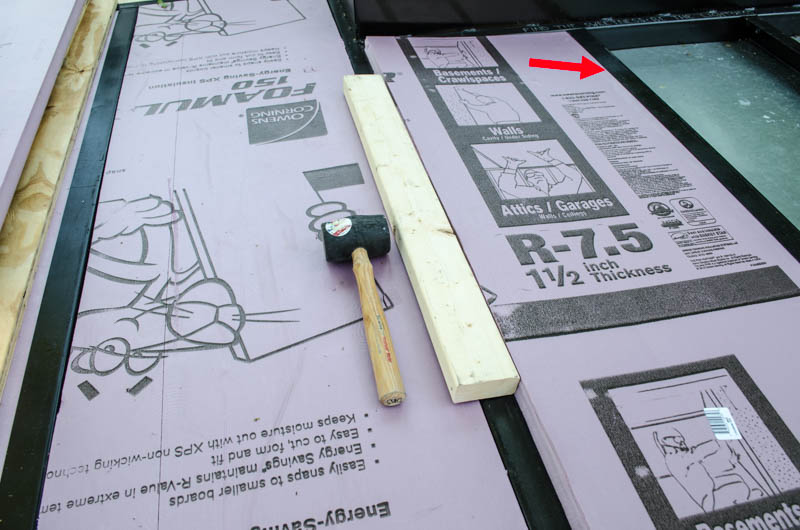

And then there’s the tricky bit of shoving those panels under the lip of the cross members (red arrow). Sure, bar soap and loosening the retainer screws holding the floor pan/flashing in place gets me some headroom, but it turns out that in some cases, even that was insufficient to accomodate the foam sheet. I needed a way to push on it, HARD, in a position where I had no body leverage to speak of. Enter the rubber mallet and 2×4 scrap (this off-cut would also qualify as a clue-by-four, if needed). This provided a means to apply a moderately sharp impulse to the edge of the foam but distributed it enough that the foam did not get damaged. Whack! Whack! Whack! In it went. Then under the trailer I went, to tighten back those screws.

I wonder if my neighbors think I’m setting off fireworks or conducting shooting practice. The snap of the XPS boards is quite sharp and not unlike small caliber gunfire.

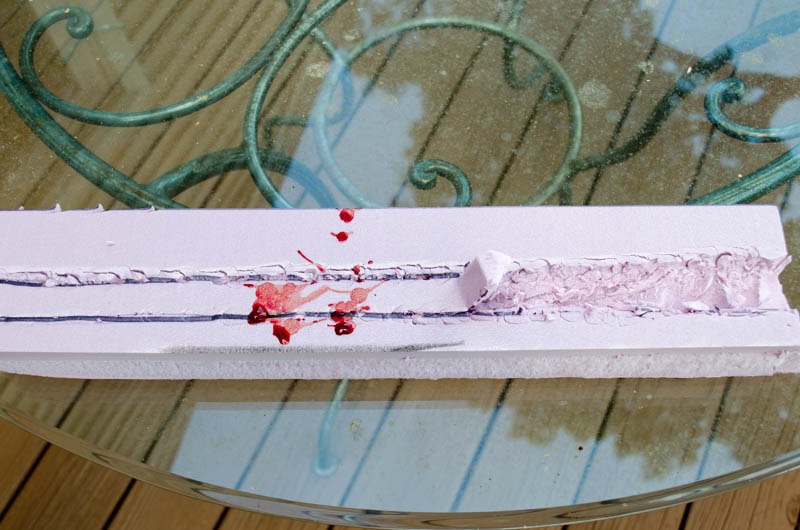

Occasionally, even the fellow some people call “Safety Man” has an accident. Shown here, a block of XPS where I was gouging out a channel for that ever-present cable. This consisted of going at the foam with a box cutter / utility knife at an angle, not unlike how the associates at Subway cut their sandwich loaves. And then I slipped, plunging the tip of the knife a moderate depth into my left hand, in the meat between thumb and forefinger. The bleeding was significant, though not “profuse”. Emergency first aid was tricky to self-administer, given that my right hand was busy applying direct pressure to stop the bleeding on my left hand… so how could I open doors, browse my first aid kit, etc., without letting go of the critical hold that was keeping the blood where it belongs (inside)?

Somehow I managed, including such creative maneuvers as applying pressure with two fingers and using the three other fingers to turn the doorknob.

I also remembered Dr Jen’s advice for emergency care of moderate cuts: super glue, applied topically (not inside), to seal it shut and hold it closed. Ever read the label on that stuff? “Bonds skin instantly” it says. Right. Sometimes that’s exactly what you need 😀

She said she thought super glue (cyanoacrylate) was actually developed for this application. Can anybody reading this confirm or refute?

Anyway, it worked, though it continued to hurt quite a bit and I wasn’t certain that what I did was sufficient attention to the wound, so I drove myself to my local urgent care center for them to have a look-see. They were impressed with the effectiveness of the glue. . . and, while they didn’t say “yes, use that if you need to”, after cleaning around it as best they could, giving me a tetanus booster (good idea), and a script for infection-prevention (good idea given the blade wasn’t necessarily clean and I didn’t have the presence of mind to wash the wound before closing it — there was a fair bit of blood, my primary concern was stopping the bleeding), the caregiver (I didn’t catch her certification level) applied…. super glue! Or, rather, something that looks and feels quite a lot like it, but was low viscosity and in a medical applicator rather than a gel in a squeeze tube, which is what I happened to have at home.

Anyway, I was in and out of there in like 30 minutes and then, of course, back to work 🙂

What I did not do was repeat the act that got me in this particular pain: removing the waste part of the channel with the knife. Instead, I plucked at it with my fingers after the initial angle cuts (where are fairly well controlled). This was slower going, but safer.

And now the project, having claimed its first blood, is an Official Construction Project (already had sweat and tears).

The script for the infection-prevention is a course of this green-on-green pill. What’s interesting to note is that it says “Lupin” on it. As in “wolf-like”. Why is this interesting? Well, the trailer chassis was made by a company called Wolf Pack. And now my med says “wolf” on it, too. I’m not saying there’s theme here, but … there’s a theme here.